Textile Engineering Student Helping to Develop Tesla Seat Covers

By Sarah Stone

If you test drive or purchase a Tesla in the next few years, you’ll probably notice the work of textile engineering (TE) student Morgan Mase.

The Wilson College of Textiles senior is postponing her fall semester in order to finish up a six month stint as a soft trim seat development intern at Tesla headquarters in California. Her team creates the final covers that go over its car seats.

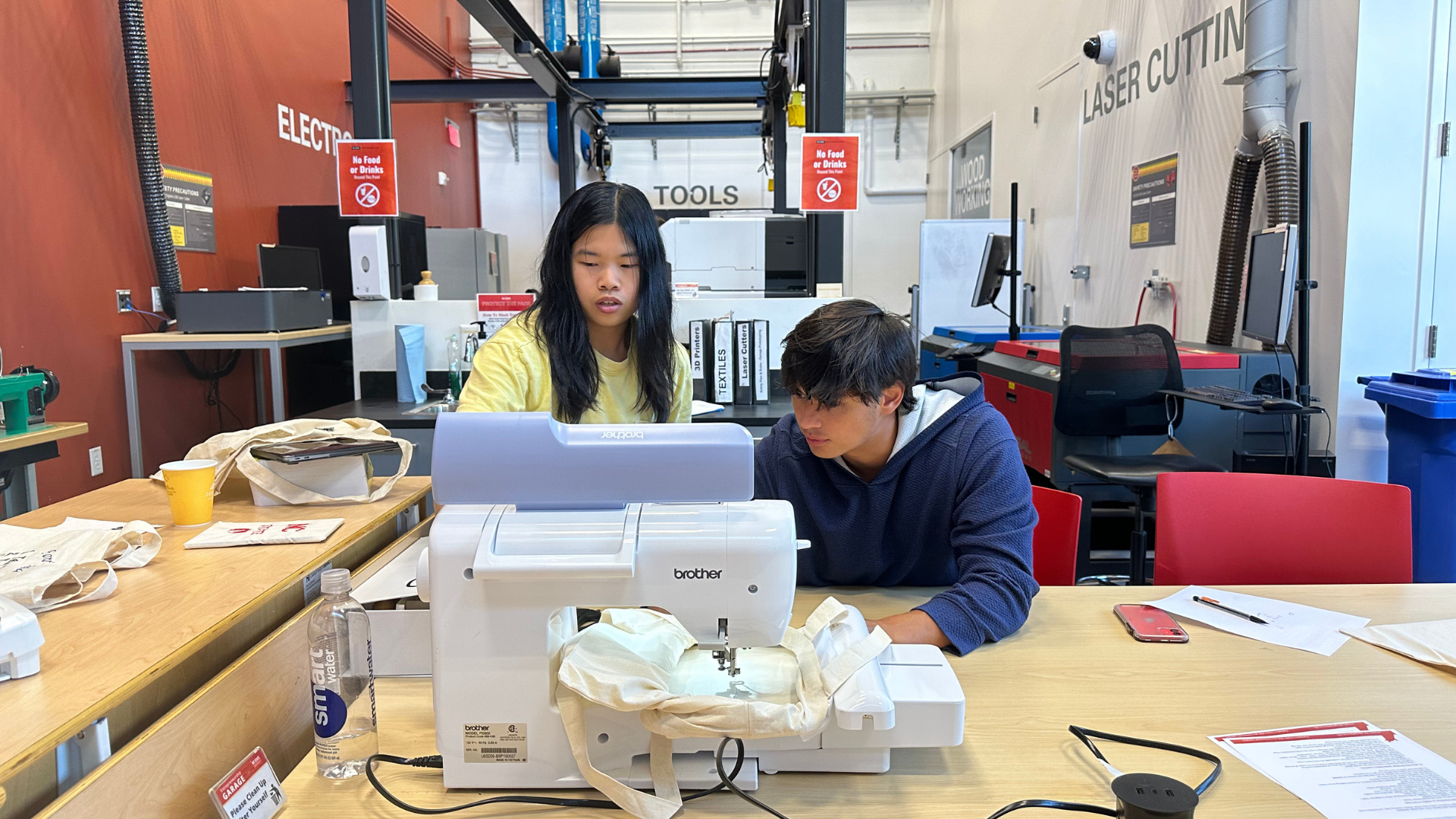

“I do a lot of work in Computer-Aided Design (CAD) software, and I’ve also gained some experience with pattern development, mastering and product life cycle management,” Mase explains. “I’ve worked on some long-term projects to improve our processes, our documentation. I’m also developing tests for the materials that we use to quantify wrinkling tendencies and other appearance issues that we want to avoid seeing in our final products. I’ve gotten the chance to sew a little bit as well for developing prototypes.”

She’s collaborating with Tesla engineers and management on projects so important they can’t be publicized, but when Mase applied she was far from familiar with her department.

“I didn’t really know what trim development was,” Mase says. “I probably couldn’t even tell you what a trim cover was.”

That didn’t matter, she says, because studying at the Wilson College gave her a leg up for this highly competitive role. Her manager says he was specifically looking for a student with both an understanding of textiles and experience applying that knowledge.

Her experience at the college continues to help Mase stand out during her time as an intern.

“I think one of the most valuable skills that I came in with that I use on a daily basis was CAD modeling, which I learned during a course at NC State,” she says. “All of my textile knowledge and experience has been quite valuable, as has my experience and knowledge with polymer science and polymer engineering in general, because I am working with textiles, but I’m also working with materials like vinyls and foams.”

While interning for Tesla, Mase says she’s honing her pattern development and mastering skills. She’s also becoming comfortable with the soft skills required to excel at a large and innovative company.

“It’s invaluable to be able to find a balance between not being pushy and being persistent to get what I want,” she says. “I also feel like I’ve learned to be flexible and adaptable. So much is changing here all the time, and I just have to be willing to pivot whenever I need to.”

Although she’d love to continue working for the soft trim department after graduation, Mase says her internship has helped her understand just how far a degree in textiles can take her.

“In collaborating with other teams at Tesla, I’ve realized what other avenues I might have the opportunity to pursue, whether that’s in materials engineering, or Color, Material and Finish Design (CMF),” she says. “This has certainly opened my eyes to all of the other industries that textiles are a part of and that I could choose to be involved in after I graduate.”

This post was originally published in Wilson College of Textiles News.